How ICEBAT Cold Thermal Energy Storage Works

Pure Thermal, as the UK partner for FAFCO’s ICEBAT, provides fully integrated CTES solutions that seamlessly integrate with existing chiller systems or can be incorporated into new projects.

ICEBAT technology uses a simple yet highly efficient process to store and release cooling energy:

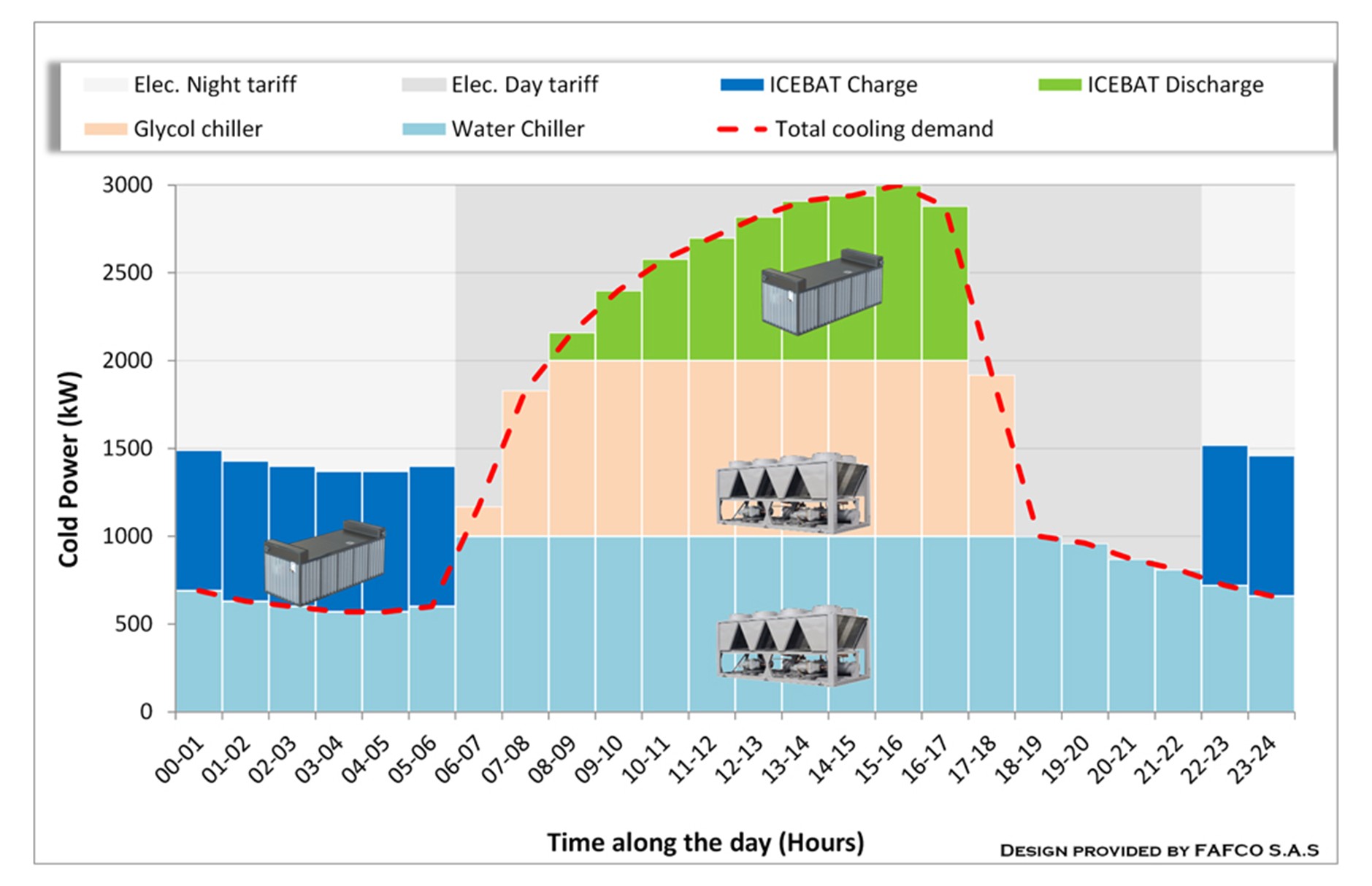

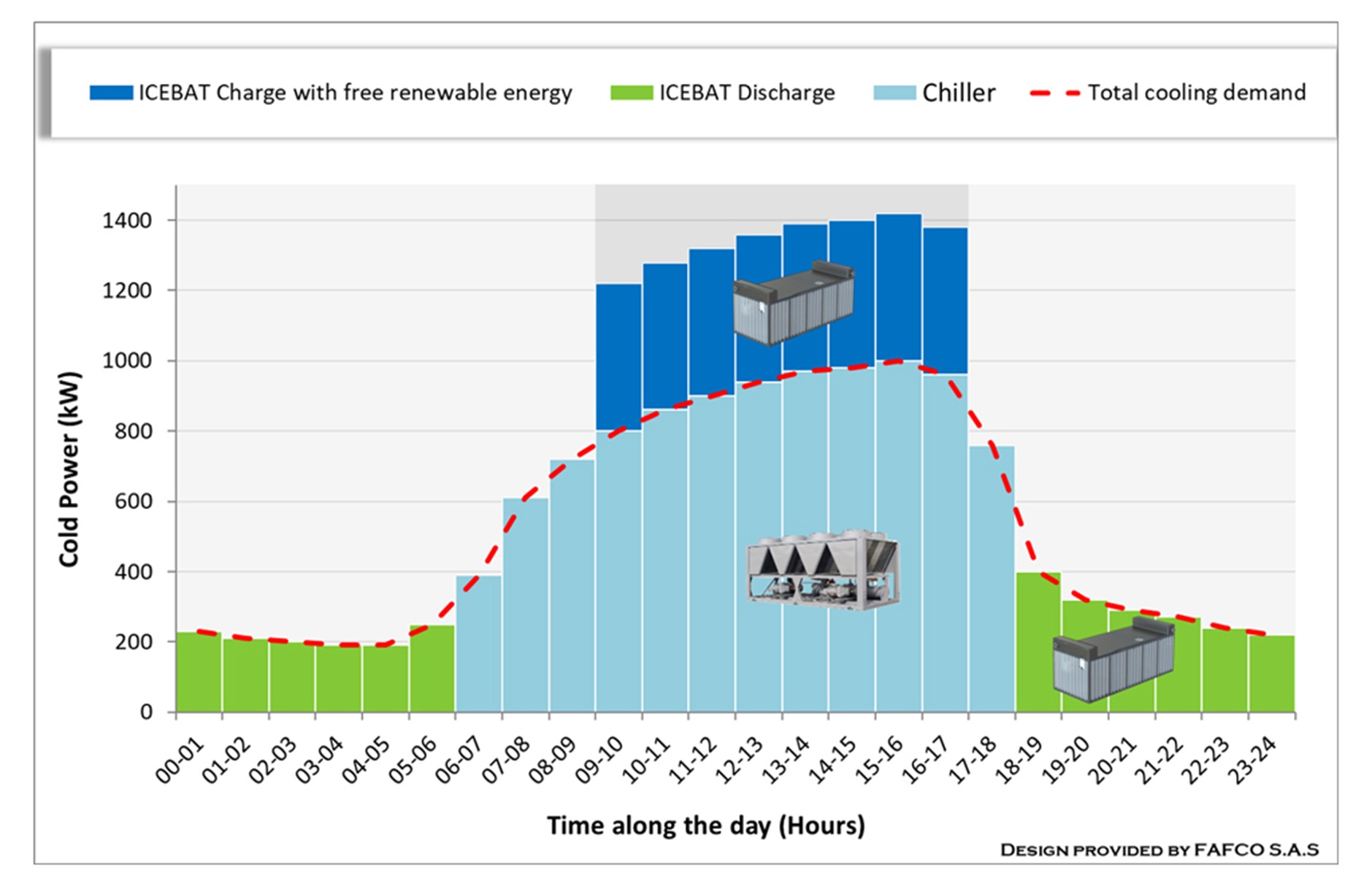

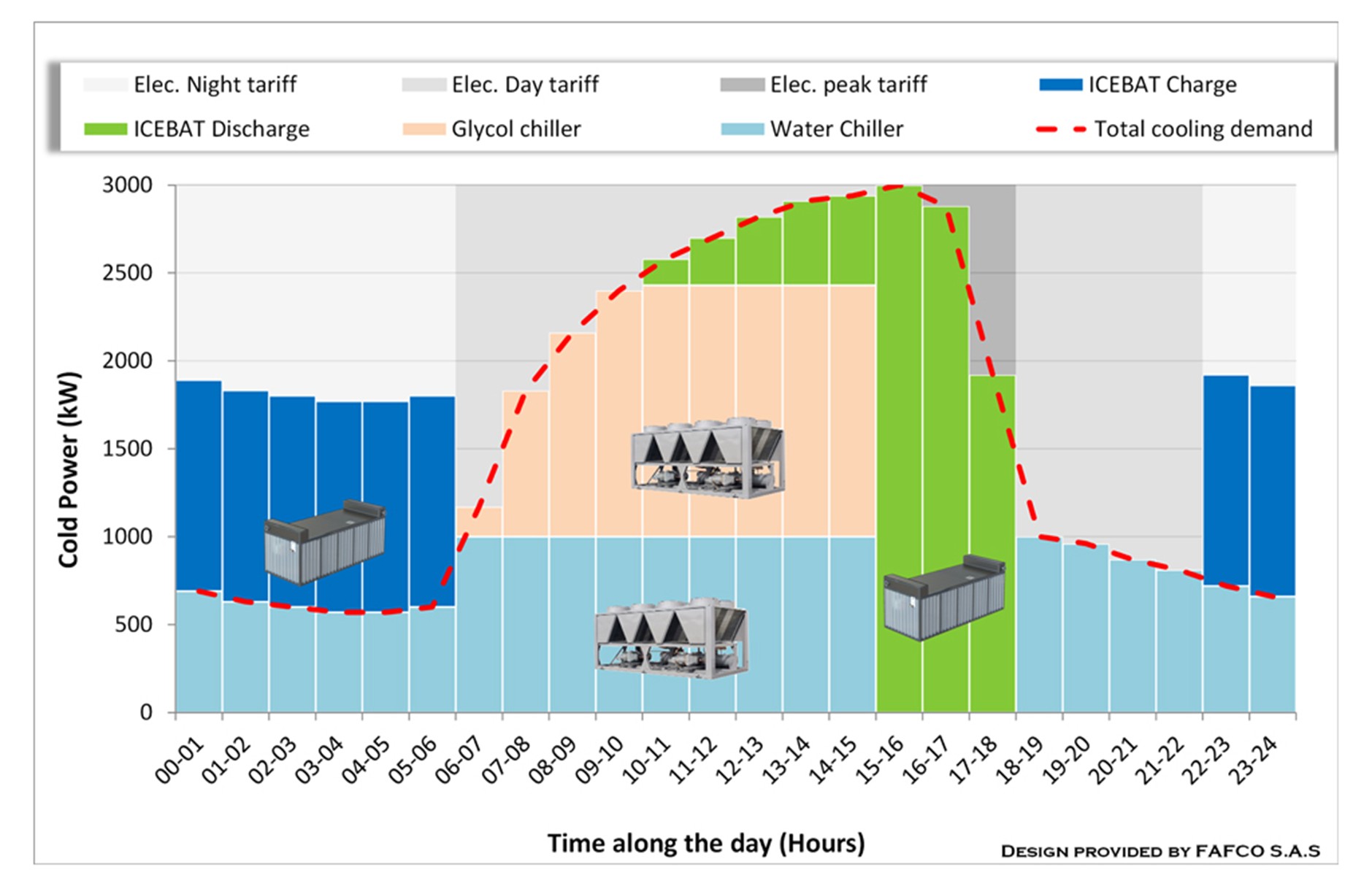

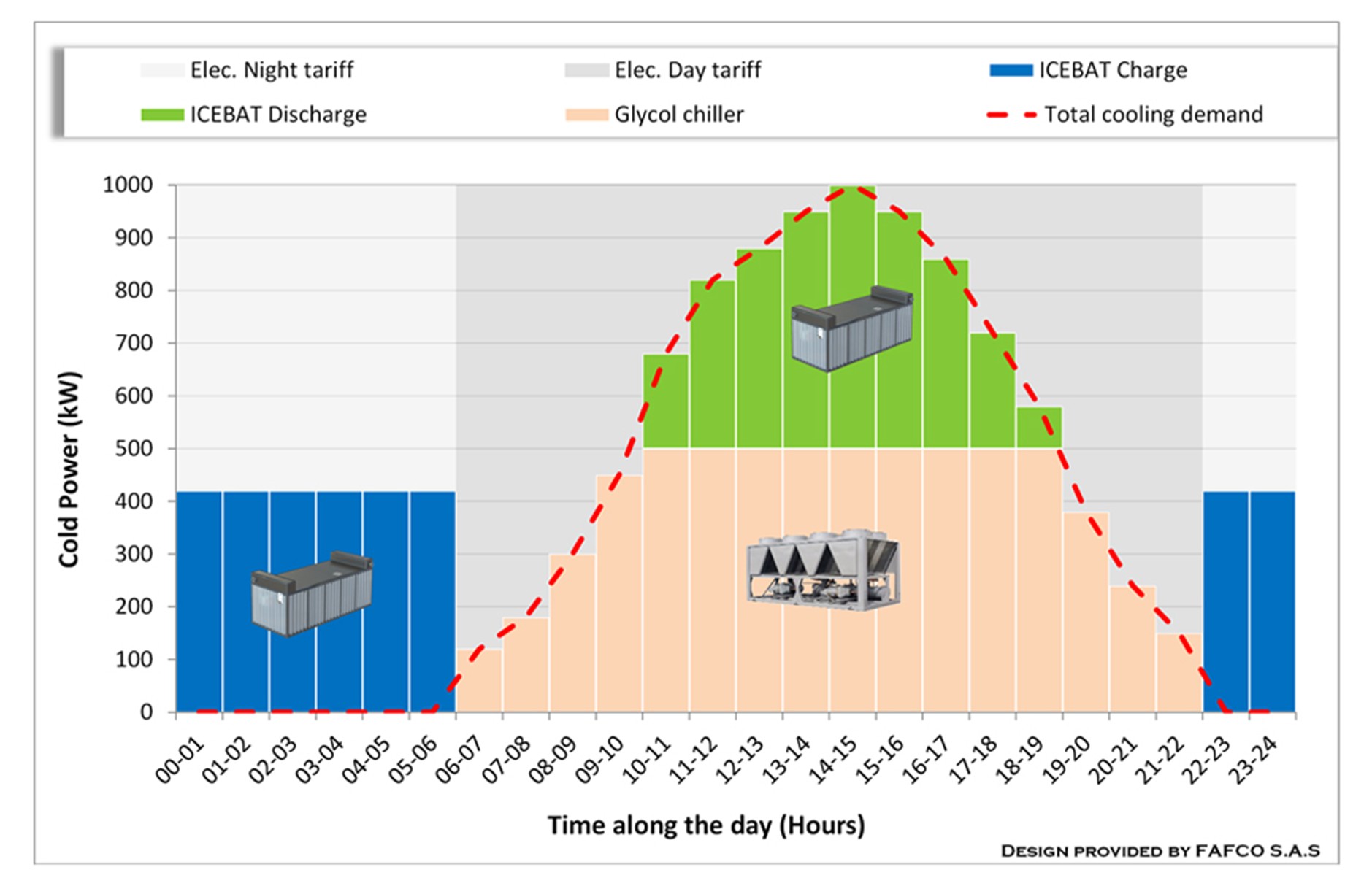

Charging the System: Water-glycol from the primary chiller circulates through ICEBAT’s patented high-performance heat exchangers, generating ice within the storage module. The system can be charged flexibly from 10kWh to 1000kWh, allowing businesses to store cooling energy when electricity is cheapest or when renewable power is available.

Discharging the System: When cooling is required, the stored ice is melted, transferring the stored cooling energy to the application via the primary chiller system or cooling loop. The system can be discharged flexibly from 10kWh to 1000kWh, ensuring on-demand cooling capacity without straining existing chiller operations.

Load Shifting: ICEBAT enables businesses to shift cooling loads away from peak electricity periods, allowing chillers to operate when electricity is cheapest while still ensuring cooling is available when needed.

This proven process provides a cost-effective, sustainable, and reliable method of managing cooling demand while reducing energy consumption and chiller wear.