Application:

A nominal capacity 2,600kWh IceBat Cold Battery Thermal Energy Storage system has been installed at this Probiotic plant providing primary cooling to the facility.

This installation, within the resilience & peak demand cold battery application sector, provides an innovative and efficient Cold Battery System to deliver primary cooling capacity to the plant.

Temperature control is clearly essential and critical within Probiotic/Dairy facilities in order to ensure efficient production is maintained.

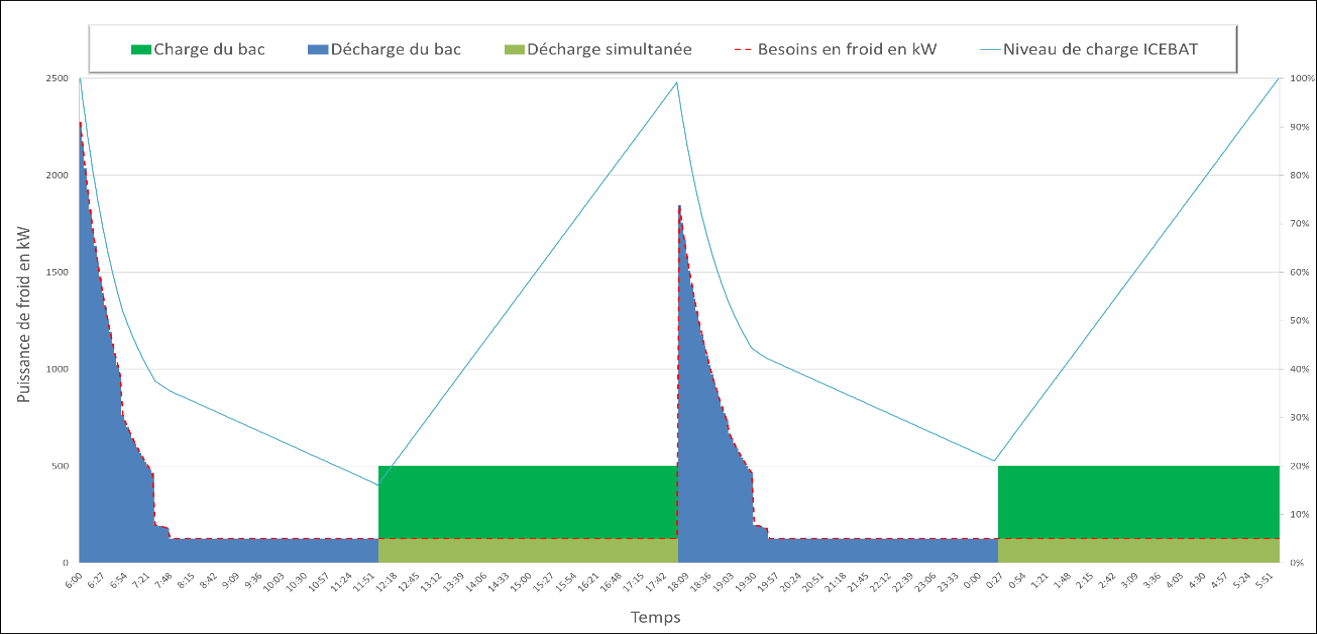

In this application the IceBat is a critical component within the cooling system design providing primary daytime peak demand capacity (2 x peaks) charged overnight by the incumbent chillers.

Additionally, the IceBat enables load shifting from heat to cooling enabling efficiency improvements to be made in terms of energy & carbon savings with a positive impact on operational cost reduction.